Laser sources

Fibre, Hybrid, Green

Use rate

Fully automatic

Adapted for high use rate

Ideal for

Permanent marking

Identification marking

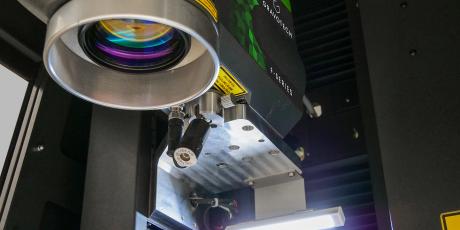

Metal engraving machine

Fibre, DPSS

From 65 x 65 mm to 205 x 205 mm

From 2.56 x 2.56'' to 8.07 x 8.07''

Metals and plastics

- Touch screen

Just press the touch screen and the LW2 laser station takes care of the rest! The door closes automatically, the laser is positioned at the right focus height, the marking is done in a few seconds and the door opens. This laser station does not require training. All you have to do is prepare your marking jobs and load them into your industrial marking solution via the USB port.

- Complete safety

This laser marking system is certified as class 1 laser products, allowing use in unrestricted environments: integrated fail-safe relay, protective glass, door closure security, emergency stop, door fitted with sensors and anti-pinch system, integrated extraction and filtration solution to protect users from dust and smoke. Mechanic and electronics are fully protected in a sealed box. Integrated alarms and controls.

- Flexibility

Large marking area with 3 sided door, marking of a wide variety of parts, from small to big parts, from simple to complex shapes. The LW2 laser station is compatible with most of our laser sources to mark on any type of material. We propose 2 software choices for the creation and control of your laser machine to adapt to your needs and varied applications: Lasertrace & Laserstyle.

Technical Specifications

Industrial marking solution compatible with the following laser sources: FIBRE, HYBRID, GREEN

Motorised and programmable vertical Z-axis

Part size up to 345mm high.

Spacious working area (l x w)

502 mm (19.764 in) x 477mm (18.78 in)

With mounting holes for accessories.

Automatic door

Opening / closing time: 2 sec

Certified Class 1 laser station, maximum safety

- Automatic door with sensors, anti-pinch and locking safety systems.

- Certified protective viewing glass (180 x 280 mm) for viewing the markings made by your industrial laser marking machine without protective glasses.

- Emergency stop button.

General

Marking Capacity

Marking area max

205 mm x 205 mm

Max object height

322 mm

Item weight

25 kg

The LW2 laser station offers a number of setting aids on the touch screen for individual use:

- Easily find the focal length thanks to the focusing diodes. Simply join the two laser diodes by adjusting the laser height with the motorised axis.

- The laser machine automatically positions itself to the focal length at the start. You only have to enter the part height directly on the screen.

- Thanks to the simulation mode, the laser engraving machine shows you the exact positioning of your future marking directly on the part.

LW2 is fully programmable to become an automated industrial laser marking machine:

- All the marking files are pre-recorded by the supervisor on the laser engraving machine.

- The entire marking process is programmable: marking information, part height, time stamping, serialisation, door opening/closing, I/O activation, etc...

- The LW2 can then switch to operator mode.

- No risk of errors, training free, just press a single button to start the next marking.

The production mode allows you to go further in managing the identification marking of your batches by connecting to your internal databases.

You thus connect the content of the marking to your databases and the history of the marked parts for an easier production process.

The metal engraving machine is controlled remotely, thanks to dedicated and programmable I/Os.

It can be integrated into a robotic cell and associated with robots or cobots.

The laser marking system speed of door opening/closing has been optimised (2s) as well as the durability of our components to allow high volume production in a difficult environment.

This allows you to feel secure about integrating our laser station on your production line. Gravotech offers you a ready-to-integrate package for a Plug and Play industrial marking solution.

LW2 in Jewellery

Rotary device

In jewellery, most objects are cylindrical. By adding a rotary device to your LW2, you complete your offer in jewellery personalisation.

Engrave on the outside and inside of rings.

Pin table

Create an air flow under your base material during laser cutting to prevent overheating. By using the cutting pin table, you raise your material by 2 cm and avoid heat deformation, beam returns and colour degradation.

50W laser

With LW2, combine the speed of galvo technology and the power of a 50 Watt laser source. Be comfortable when cutting and fast when engraving for maximum efficiency.

This laser station can mark +25 materials

| FIBER GALVO | HYBRID | GREEN | |

|---|---|---|---|

| ORGANICS | |||

| Ceramic | |||

| Electrical and medical ceramic | |||

| Leather | |||

| Paper, cardboard, cork | |||

| Rubber | |||

| Silicon | |||

| Wood, varnished wood | |||

| PLASTICS | |||

| ABS | |||

| Laminates | |||

| PA | |||

| PE, BET | |||

| PMMA, Acrylic | |||

| POM - PBT | |||

| PP | |||

| PC | |||

| Foam | |||

| METAL | |||

| Aluminum | |||

| Anodized Aluminum | |||

| Brass | |||

| Carbide | |||

| Coated metal | |||

| Copper | |||

| Gold, silver, nickel, platinum | |||

| Stainless steel | |||

| Steel | |||

| Titanium | |||